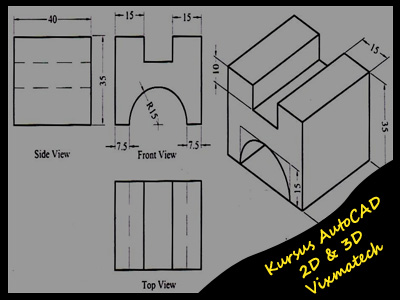

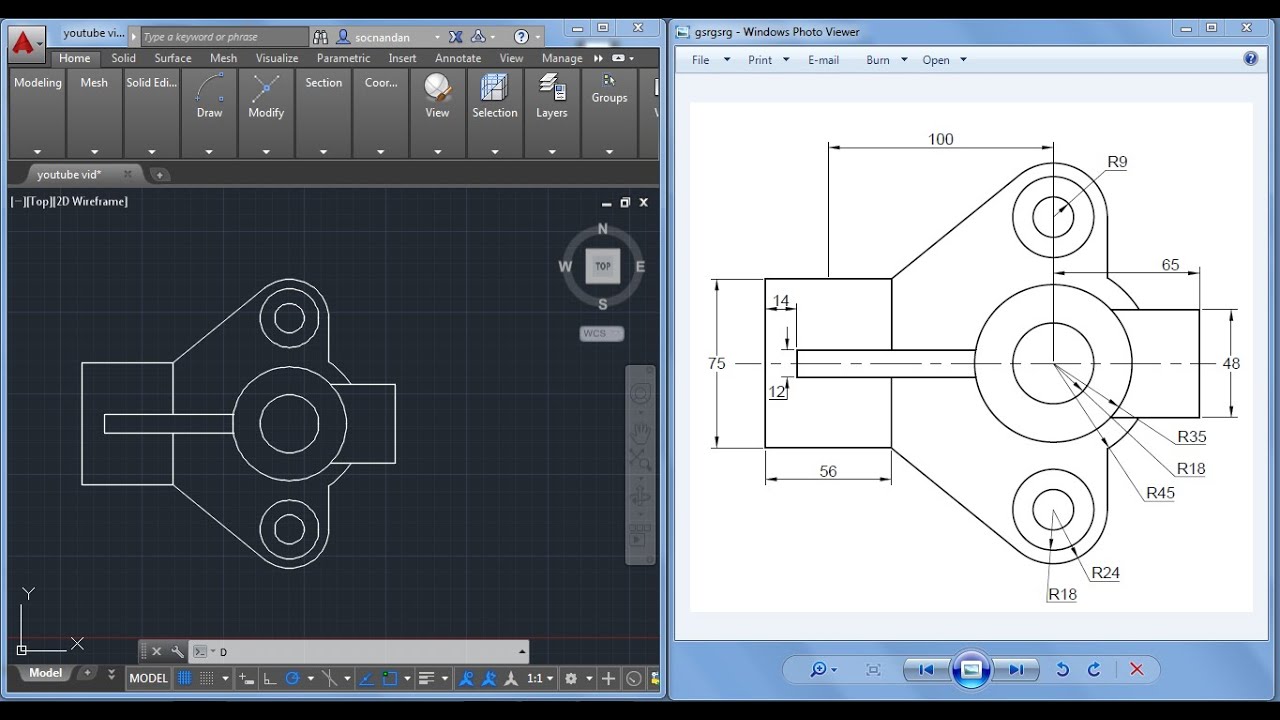

We close the sketch and pocket the hole though all the material. We select the circle and add a constraint to make its radius 2mm. Now the circle still has an arbitrary size. If you get close to an existing point and it turns yellow the point is catched and a constraint is automatically created. These are also sketches on the surface that are then pocketed through the piece.Ĭreating sketches in FreeCAD follows a simple logic. The two long pieces get holes to mount the cooling unit and screw the mount to the cart. We repeat the same steps for the other supporting structure. With the multiline tool we then draw a triangle and directly close the sketch.īy pocketing the triangle through the entire structure we cut away part of the shape. Before we can modify a shape we have to convert it into a body with the button showing a blue staircase.įor the smaller pieces we create a sketch on their surface and then use the button with the blue box to get the corners of the shape as a reference. Now we switch back to the part design workbench to modify the pieces. Refinement with the parts design workbench While for the short sides the default setting of a single tab works fine we increase the amount of tabs for the long sides to five.Īfter hiding the second long side we can add the other two faces and after closing the task panel all the tabs are created. By pressing space we hide one long piece and mark the faces of two short pieces so that they get tabs. In the task panel we add all parts to the assembly with the add same parts button. We then select all the pieces and click on the button to create connection tabs. Just type the plus sign and the number and let FreeCAD do the math for you. To move objects by a set amount we add the respective number in the positioning area. We delete the two sides that we don’t need with the delete key and position the two sides that later will become supporting elements 30 mm inwards.

We just fill in the width, height, length of the box and the the thickness of the material – which is 3.1 millimeter – and get a box of that size. The box design tool from the workbench gives us a head start and creates the necessary pieces easily. We want the mounts to have a length of 150 mm and the short sides to be around 25 mm wide. Designing the shape with the laser cut interlocking workbench In FreeCAD we switch to the LC Interlocking workbench. Install the workbench following the instructions on the website. The LC Interlocking Workbench is a great way to design even quite complicated shapes for the laser cutter. This is a bit too complicated to model as a simple 2d model in Inkscape as we have shownįreeCAD however is easily able to handle this design.

These mounting brackets are designed to hold the cooling unit of the K40 that we build here. We will create a simple mounting bracket as an example. In this article we will design 3D objects for laser cutting using the free and open source CAD software FreeCAD.

0 kommentar(er)

0 kommentar(er)